What Are Transformer Losses: An In-Depth Explanation

Transformers are essential components of electrical power systems that play a vital role in transferring electrical energy from one circuit to another. However, like any other electrical equipment, transformers also experience some losses during operation, which can have a significant impact on their efficiency, performance, and overall cost of operation. In this article, we will provide a comprehensive explanation of transformer losses, their types, causes, and ways to minimize them.

Table of Contents

- Introduction

- Transformer Basics

- Types of Transformer Losses

- Core Losses

- Hysteresis Losses

- Eddy Current Losses

- Copper Losses

- Ohmic Losses

- Leakage Losses

- Ways to Reduce Transformer Losses

- Core Design

- Core Material

- Winding Design

- Operating Voltage

- Conclusion

- FAQs

1. Introduction

Transformer losses refer to the amount of power that is dissipated in the form of heat due to various physical phenomena during the operation of a transformer. These losses are mainly caused by two factors: core losses and copper losses. Core losses are associated with the magnetic properties of the transformer’s core, while copper losses are caused by the resistance of the transformer’s winding.

Transformer losses have a direct impact on the efficiency of the transformer, which is defined as the ratio of the output power to the input power. The higher the losses, the lower the efficiency, and the more energy is wasted. Therefore, minimizing transformer losses is crucial for improving the efficiency and reducing the operational cost of transformers.

2. Transformer Basics

Before delving into the details of transformer losses, let’s first understand the basic operation of transformers. A transformer is a device that transfers electrical energy from one circuit to another through electromagnetic induction. It consists of two coils, primary and secondary, that are wrapped around a common iron core.

When an alternating current flows through the primary coil, it generates a magnetic field that induces a voltage in the secondary coil. The voltage induced in the secondary coil is proportional to the ratio of the number of turns in the primary and secondary coils. Therefore, by choosing the appropriate number of turns in the coils, transformers can be designed to step up or step down the voltage level of the electrical power.

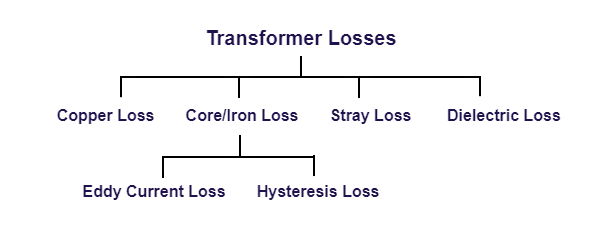

3. Types of Transformer Losses

There are two main types of transformer losses: core losses and copper losses. Core losses are further classified into hysteresis losses and eddy current losses, while copper losses are divided into ohmic losses and leakage losses.

4. Core Losses

Core losses, also known as iron losses, are associated with the magnetic properties of the transformer’s core. These losses are caused by two phenomena: hysteresis and eddy currents.

4.1 Hysteresis Losses

Hysteresis losses occur due to the reversal of magnetization in the transformer’s core. When the magnetic field is applied to the core, it aligns the magnetic domains in the same direction. However, when the magnetic field is removed or reversed, the magnetic domains do not return to their original state, and some energy is dissipated in the form of heat. Hysteresis losses are proportional to the frequency and the magnetic properties of the core material.

4.2 Eddy Current Losses

Eddy current losses occur due to the circulation of currents within the transformer’s core. When the magnetic field changes, it induces a voltage in the core, which, in turn, generates eddy currents. These currents flow in closed loops and cause energy to be dissipated in the form of heat. Eddy current losses are proportional to the square of the frequency and the thickness of the core laminations.

5. Copper Losses

Copper losses, also known as winding losses, are caused by the resistance of the transformer’s winding. These losses are further divided into two types: ohmic losses and leakage losses.

5.1 Ohmic Losses

Ohmic losses occur due to the resistance of the transformer’s winding. When a current flows through the winding, some energy is dissipated in the form of heat due to the resistance of the winding material. Ohmic losses are proportional to the square of the current and the resistance of the winding.

5.2 Leakage Losses

Leakage losses occur due to the leakage flux that is present in the transformer. Leakage flux is the magnetic flux that does not link the primary and secondary windings and flows through the air or the insulation between the windings. This flux generates eddy currents in nearby conductive materials, such as the transformer’s core or the surrounding metal structures, which cause energy to be dissipated in the form of heat. Leakage losses are proportional to the square of the current and the leakage inductance of the transformer.

6. Ways to Reduce Transformer Losses

Minimizing transformer losses is crucial for improving the efficiency and reducing the operational cost of transformers. Here are some ways to reduce transformer losses:

6.1 Core Design

The core design of the transformer plays a significant role in reducing core losses. Using thinner core laminations can reduce eddy current losses, while using high-permeability materials can reduce hysteresis losses. The core can also be designed to reduce the flux density in the core, which can reduce both hysteresis and eddy current losses.

6.2 Core Material

The core material of the transformer is also important in reducing core losses. Using high-quality, low-loss materials, such as silicon steel, can significantly reduce hysteresis and eddy current losses.

6.3 Winding Design

The winding design of the transformer can also affect copper losses. Using larger conductor sizes can reduce ohmic losses, while reducing the length of the winding can reduce leakage losses.

6.4 Operating Voltage

Operating the transformer at the optimal voltage level can also reduce losses. Operating at a higher voltage can reduce copper losses, while operating at a lower voltage can reduce core losses.

7. Conclusion

Transformer losses are an important aspect of transformer design and operation. Core losses and copper losses are the two main types of losses that can significantly impact the efficiency and cost of operation of transformers. Minimizing losses through core design, core material, winding design, and operating voltage can improve the efficiency and reduce the operational cost of transformers.

8. FAQs

- What is the efficiency of a transformer?

- The efficiency of a transformer is the ratio of the output power to the input power. It represents the percentage of energy that is transferred from the primary to the secondary circuit.

- How do hysteresis losses occur in transformers?

- Hysteresis losses occur in transformers due to the reversal of magnetization in the transformer’s core. When the magnetic field is removed or reversed, the magnetic domains do not return to their original state, and some energy is dissipated in the form of heat.

- What is the difference between hysteresis losses and eddy current losses?

- Hysteresis losses are caused by the reversal of magnetization in the transformer’s core, while eddy current losses are caused by the circulation of currents within the transformer’s core.

- How can copper losses be minimized in transformers?

- Copper losses can be minimized by using larger conductor sizes and reducing the length of the winding. These measures can reduce the resistance of the winding, thereby reducing the ohmic losses.

- What is the effect of operating voltage on transformer losses?

- Operating the transformer at the optimal voltage level can reduce losses. Operating at a higher voltage can reduce copper losses, while operating at a lower voltage can reduce core losses.