In today’s fast-paced world, efficiency, and error reduction have become paramount in various industries. One methodology that has gained significant attention for achieving this is the concept of “Poka Yoke.” In this article, we’ll delve into the depths of Poka Yoke, exploring its origins, principles, and how it is implemented across different sectors.

Table of Contents

- Introduction

- Origin of Poka Yoke

- Understanding Poka Yoke

- 3.1 Definition

- 3.2 Key Principles

- Types of Poka Yoke

- 4.1 Contact Poka Yoke

- 4.2 Fixed Value Poka Yoke

- 4.3 Motion Step Poka Yoke

- Real-world Applications

- 5.1 Manufacturing

- 5.2 Healthcare

- 5.3 Software Development

- Benefits of Implementing Poka Yoke

- Challenges and Considerations

- Successful Poka Yoke Stories

- How to Implement Poka Yoke

- 9.1 Step-by-Step Guide

- 9.2 Training and Culture

- Poka Yoke vs Six Sigma

- Future Trends in Poka Yoke

- Examples of Poka Yoke in Everyday Life

- Criticisms and Debates

- Success Factors and Key Takeaways

- Conclusion

Introduction:

Poka Yoke, a Japanese term meaning “mistake-proofing” or “inadvertent error prevention,” is a quality management concept that has revolutionized the way industries approach operational efficiency and defect prevention.

Origin of Poka Yoke:

The roots of Poka Yoke can be traced back to Japan in the 1960s, where it was developed by Shigeo Shingo, an industrial engineer. Shingo aimed to create a system that would eliminate errors at the source, rather than relying on inspections or corrections after the fact.

Understanding Poka Yoke:

3.1 Definition:

Poka Yoke is a set of techniques or mechanisms designed to prevent errors and defects during the manufacturing or operational process.

3.2 Key Principles:

The core principles of Poka Yoke include identifying and eliminating potential sources of error, simplifying processes, and providing foolproof mechanisms to ensure flawless execution.

Types of Poka Yoke:

4.1 Contact Poka Yoke:

This type relies on physical contact to prevent errors. For instance, a sensor preventing a machine from operating if a crucial component is missing.

4.2 Fixed Value Poka Yoke:

Involves setting specific parameters to ensure a process cannot proceed if conditions are not met, guaranteeing quality control.

4.3 Motion Step Poka Yoke:

Focuses on the sequence of steps in a process, ensuring that they are followed in the correct order, reducing the likelihood of errors.

Real-world Applications:

5.1 Manufacturing:

Poka Yoke has found extensive application in manufacturing, reducing defects and improving overall product quality.

5.2 Healthcare:

In healthcare settings, it helps prevent medical errors and enhances patient safety through meticulous process design.

5.3 Software Development:

Even in the realm of software development, Poka Yoke principles can be applied to minimize coding errors and streamline development workflows.

Benefits of Implementing Poka Yoke:

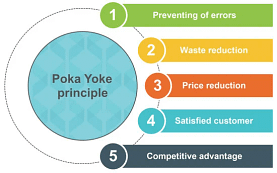

Implementing Poka Yoke comes with a plethora of benefits, such as reduced defects, enhanced product quality, increased productivity, and improved customer satisfaction.

Challenges and Considerations:

While Poka Yoke is a powerful tool, challenges such as resistance to change and initial implementation costs need to be addressed for successful integration.

Successful Poka Yoke Stories:

Highlighting real-world success stories where Poka Yoke has led to significant improvements in efficiency, quality, and customer satisfaction.

How to Implement Poka Yoke?

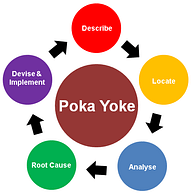

9.1 Step-by-Step Guide:

A practical guide outlining the steps to effectively implement Poka Yoke in any operational setting.

9.2 Training and Culture:

The importance of creating a culture that values error prevention and provides adequate training for successful Poka Yoke implementation.

Poka Yoke vs Six Sigma:

Comparing Poka Yoke with the Six Sigma methodology, exploring their differences and synergies in achieving operational excellence.

Future Trends in Poka Yoke:

Analyzing emerging trends and advancements in Poka Yoke, including technological innovations and evolving applications.

Examples of Poka Yoke in Everyday Life:

Exploring how Poka Yoke is subtly integrated into various aspects of our daily routines, often without us realizing it.

Criticisms and Debates:

Addressing criticisms and debates surrounding Poka Yoke, acknowledging that no system is without its challenges.

Success Factors and Key Takeaways:

Summarizing the critical success factors and key takeaways for organizations looking to embrace Poka Yoke for continuous improvement.

Conclusion:

In conclusion, Poka Yoke stands as a beacon of proactive error prevention, shaping industries towards enhanced efficiency and unparalleled quality. Its principles can be universally applied, fostering a culture of continuous improvement.

Your feedback matters! Please let me know how I did with a thumbs up!

FAQs:

-

- What industries benefit the most from Poka Yoke implementation?

- Industries with intricate manufacturing processes, such as automotive and electronics, often benefit the most.

- How long does it take to see noticeable improvements after implementing Poka Yoke?

- The timeline varies, but organizations typically witness positive changes within a few weeks to a few months.

- Are there any notable failures in Poka Yoke implementation?

- While rare, some instances of failure exist, often attributed to insufficient training or resistance to change.

- Can Poka Yoke principles be applied to service-based industries?

- Yes, Poka Yoke principles can be adapted to service industries, emphasizing process simplification and error prevention.

- What role does employee training play in successful Poka Yoke implementation?

- Employee training is pivotal; a well-trained workforce is essential for understanding and embracing Poka Yoke principles.

- What industries benefit the most from Poka Yoke implementation?