Dial Gauge: An In-Depth Guide:

Written By: Er. PARAMESWAR MURMU

If you are looking for a reliable and accurate measurement tool, dial gauges are a popular choice among professionals. These instruments are used in various industries to measure dimensions accurately, such as mechanical engineering, manufacturing, and automotive repair. In this guide, we will explore everything you need to know about dial gauges, including their uses, types, and benefits.

Table of Contents :

-

Introduction of Dial Gauge:

- Definition of a Dial Gauge

- Importance in Various Industries

-

Components of a Dial Gauge:

- Dial Face

- Pointer

- Bezel

- Case

-

Types of Dial Gauges:

- Dial Test Indicators

- Dial Indicators

- Digital Dial Gauges

-

How Dial Gauges Work?

- Mechanical Operations

- Digital Mechanisms

-

Applications in Metrology:

- Precision Measurements

- Quality Control

- Engineering and Manufacturing

-

Choosing the Right Dial Gauge:

- Considerations for Specific Applications

- Accuracy and Precision

-

Proper Calibration and Maintenance:

- Importance of Regular Calibration

- Maintenance Tips for Prolonged Lifespan

-

Advantages and Limitations:

- Advantages in Various Industries

- Limitations and Workarounds

-

Case Studies:

- Case Study 1: Automotive Manufacturing

- Case Study 2: Aerospace Engineering

-

Emerging Trends in Dial Gauge Technology:

- Integration with IoT

- Advances in Digital Interfaces

-

Conclusion:

-

FAQs:

What is a Dial Gauge and Why Does It Matter?

Dial gauges play a pivotal role in the world of metrology, engineering, and manufacturing. These precision instruments provide accurate measurements, contributing significantly to the quality control processes in various industries. Let’s delve into the intricacies of dial gauges, exploring their components, types, applications, and the evolving landscape of this essential tool.

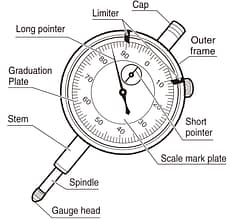

Components of a Dial Gauge:

Dial gauges consist of several key components that work in harmony to deliver precise measurements.

I: Dial Face:

The dial face is the marked surface displaying measurement units. It serves as the reference point for reading measurements accurately.

II: Pointer:

The pointer, often a needle, moves across the dial face, indicating the measured value. Its design and materials contribute to the overall accuracy of the gauge.

III: Bezel:

The bezel is the outer ring surrounding the dial face. It aids in adjusting the zero point and may have additional features depending on the gauge type.

IV: Case:

The case encloses the internal components, protecting external factors. It is designed to ensure the gauge’s durability and longevity.

Types of Dial Gauges:

There are various types of dial gauges available, each with its unique features and benefits. Some of the most common types are:

1. Plunger Dial Gauge:

The plunger dial gauge, also known as a dial test indicator, is a type of dial gauge used to measure small distances accurately. This gauge has a spring-loaded plunger that moves in and out of the gauge’s body, providing precise measurements of the object’s dimensions.

2. Dial Depth Gauge:

A dial depth gauge is a type of dial gauge used to measure the depth of holes, grooves, and slots accurately. This gauge has a base that rests on the object’s surface, and the dial indicator provides a precise reading of the measurement.

3. Dial Bore Gauge:

A dial bore gauge is a type of dial gauge used to measure the inside diameter of holes, such as engine cylinders, with high accuracy. This gauge has a small anvil that is placed inside the hole, and the dial indicator provides an accurate measurement of the bore’s diameter.

4. Dial Thickness Gauge:

A dial thickness gauge is a type of dial gauge used to measure the thickness of materials such as paper, plastic, and metals accurately. This gauge has a base that rests on the material, and the dial indicator provides a precise reading of the measurement.

How Dial Gauges Work?

The operational mechanisms of dial gauges vary based on their type.

I: Mechanical Operations:

Traditional dial gauges rely on mechanical systems involving gears and springs. The movement of the pointer corresponds directly to the physical displacement being measured.

II: Digital Mechanisms:

Digital dial gauges, on the other hand, use electronic sensors to detect displacements. The measured values are then displayed digitally, providing accuracy and ease of use.

Applications in Metrology:

Dial gauges find widespread applications in the field of metrology.

I: Precision Measurements:

Instruments like dial indicators are crucial for obtaining precise measurements, and ensuring components meet required specifications.

II: Quality Control:

Industries such as automotive and aerospace heavily rely on dial gauges for quality control, guaranteeing products adhere to strict standards.

III: Engineering and Manufacturing:

Dial gauges play a pivotal role in the manufacturing process, aiding in the production of components with high precision.

Choosing the Right Dial Gauge:

Selecting the appropriate dial gauge involves considering specific application requirements.

I: Considerations for Specific Applications

Different industries and tasks demand varying features. Understanding the specific needs ensures the chosen gauge aligns with the application.

II: Accuracy and Precision

Accuracy and precision are paramount. Depending on the required tolerances, selecting a gauge with the right level of accuracy is crucial.

Proper Calibration and Maintenance:

To maintain the reliability of dial gauges, regular calibration, and proper maintenance are essential.

I: Importance of Regular Calibration

Regular calibration ensures the gauge provides accurate readings. Deviations can be identified and corrected, preventing errors in measurements.

II: Maintenance Tips for Prolonged Lifespan

Simple maintenance practices, such as keeping the gauge clean and storing it in a protective case, contribute to its prolonged lifespan.

Advantages and Limitations:

Dial gauges offer several advantages over other measuring tools, such as:

Advantages in Various Industries:

Dial gauges offer unparalleled precision, making them indispensable in industries where accuracy is paramount.

I: High Accuracy: Dial gauges are known for their high accuracy and precision, making them an ideal choice for applications that require precise measurements.

II: Versatility: Dial gauges can be used to measure a wide range of dimensions, such as depth, diameter, and thickness, making them versatile instruments.

III: Easy to Use: Dial gauges are relatively easy to use, and the readings are easy to interpret, making them an ideal choice for both professionals and beginners.

Limitations and Workarounds:

While highly accurate, dial gauges may have limitations in certain environments. Employing workarounds, such as protective housing, can mitigate these challenges.

Case Studies:

Real-world examples highlight the practical applications of dial gauges.

Case Study 1: Automotive Manufacturing:

In the automotive industry, dial gauges are employed to ensure engine components meet strict tolerances, contributing to the reliability of vehicles.

Case Study 2: Aerospace Engineering:

Aerospace engineers use dial gauges to measure critical dimensions in aircraft components, ensuring safety and performance.

Emerging Trends in Dial Gauge Technology:

The landscape of dial gauges is evolving with technological advancements.

I: Integration with IoT:

Dial gauges are increasingly being integrated with the Internet of Things (IoT), allowing for remote monitoring and data analysis.

II: Advances in Digital Interfaces:

Digital dial gauges continue to see improvements in user interfaces, enhancing user experience and data accessibility.

Your feedback matters! Please let me know how I did with a thumbs up!

Conclusion:

Dial gauges are versatile and reliable measuring tools used in various industries to measure dimensions accurately. They offer several advantages, such as high accuracy, versatility, and ease of use, making them an ideal choice for professionals and beginners alike.

FAQs Of Dial Gauge:

Q. Can dial gauges be calibrated?

A. Yes, dial gauges can be calibrated to ensure their accuracy. This process involves comparing the gauge’s readings to a known standard and adjusting the gauge accordingly.

Q. What is the range of measurement for a dial gauge?

A. The range of measurement for a dial gauge can vary depending on the type and model. Some gauges can measure up to several inches, while others are designed for very small measurements.

Q. Can dial gauges be used for both metric and imperial measurements?

A. Yes, many dial gauges are designed to display measurements in both metric and imperial units.

Q. Are there any special precautions to take when using a dial gauge?

A. Yes, it is important to handle dial gauges carefully and avoid dropping or subjecting them to rough handling. It is also important to ensure that the gauge is properly zeroed before taking a measurement.

Q. What are some common applications for dial gauges?

A. Dial gauges are used in many industries, including mechanical engineering, manufacturing, and automotive repair. They are often used to measure dimensions such as depth, diameter, and thickness with high accuracy.

Q. What is the difference between a dial gauge and a digital gauge?

A. A dial gauge has an analog display that shows measurements on a dial face, while a digital gauge displays measurements on a digital screen. Digital gauges often have more features and can be more precise, but dial gauges are typically more affordable and easier to read.

This is a very informative article. It really sparked my interest on several points. I agree with most of the points and am currently pondering the rest. Thank you for keeping your information so engaging.

Nice post I like the layout of your page by the way.