Micrometer:

The Precision Tool for Accurate Measurements

When it comes to measuring small distances with high precision, a micrometer is the go-to tool. Whether you’re a machinist, engineer, or hobbyist, a micrometer can help you achieve accurate measurements to within a few thousandths of an inch or hundredths of a millimeter. In this article, we’ll dive deep into the world of micrometers, exploring their history, types, uses, and maintenance.

Table of Contents

What is a Micrometer?

History of Micrometers

Types of Micrometers

Outside Micrometer

Inside Micrometer

Depth Micrometer

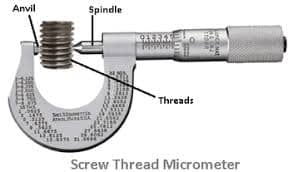

Screw Thread Micrometer

How to Use a Micrometer

Accuracy of Micrometers

Calibration and Maintenance

Advantages of Using Micrometers

Disadvantages of Using Micrometers

Micrometer vs. Vernier Caliper

Micrometer vs. Dial Indicator

Micrometer Applications

Automotive Industry

Aviation Industry

Manufacturing Industry

Research and Development

Micrometer Prices

Conclusion

FAQs

What is a Micrometer?

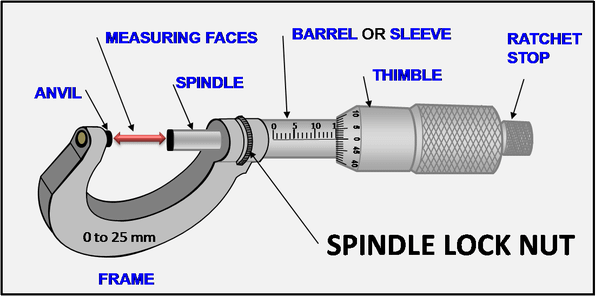

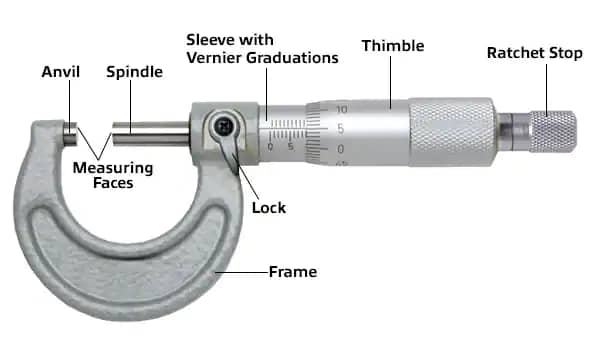

A micrometer, also known as a micrometer screw gauge, is a precision measuring tool used to measure small distances with high accuracy. It consists of a calibrated screw and a measuring scale, which is usually graduated in thousandths of an inch or hundredths of a millimeter. The screw is turned by a thimble or ratchet, and the scale moves in relation to the screw’s rotation, allowing the user to read the measurement.

History of Micrometers

The micrometer was invented in the early 17th century by a French mathematician named Jean-Baptiste de Gribeauval. However, it was not until the 19th century that micrometers became widely used in industry, thanks to their precision and ease of use. Today, micrometers are essential tools in many fields, from engineering and manufacturing to medicine and science.

Types of Micrometers

There are several types of micrometers, each designed for specific applications. Some of the most common types include:

Outside Micrometer

The outside micrometer, also known as a micrometer caliper, is used to measure the external diameter of an object. It consists of a C-shaped frame, a measuring spindle, and an anvil. The spindle is moved towards the anvil by turning the thimble, and the measurement is read from the scale on the thimble.

Inside Micrometer

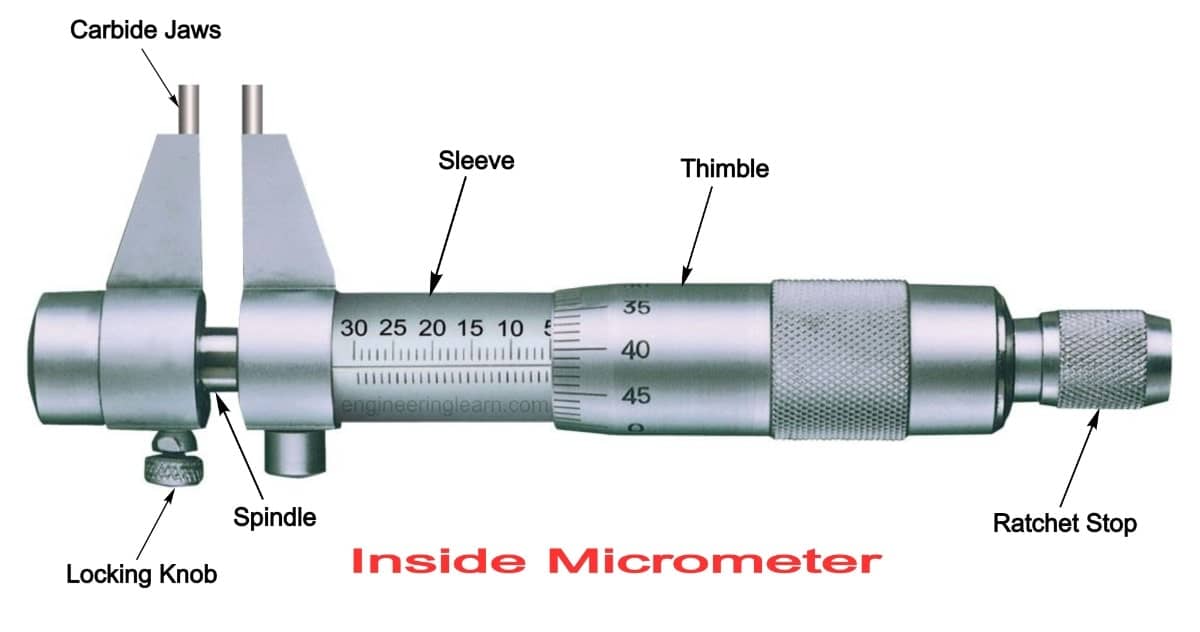

The inside micrometer, also known as a bore gauge, is used to measure the internal diameter of a hole or tube. It consists of a C-shaped frame, a measuring spindle, and two extension rods. The spindle is inserted into the hole or tube, and the measurement is read from the scale on the thimble.

Depth Micrometer

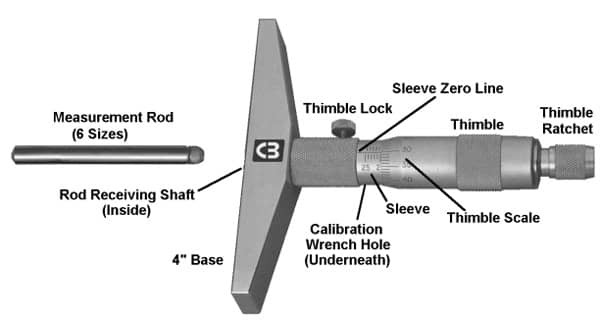

The depth micrometer, also known as a depth gauge, is used to measure the depth of a hole or slot. It consists of a base, a measuring rod, and a measuring spindle. The measuring rod is inserted into the hole or slot, and the measurement is read from the scale on the thimble.

Screw Thread Micrometer

The screw thread micrometer, also known as a thread pitch micrometer, is used to measure the pitch diameter of a screw thread. It consists of a C-shaped frame, a measuring spindle, and an anvil. The spindle is placed on the screw thread, and the measurement is read from the scale on the thimble.

How to Use a Micrometer

Using a micrometer requires some skill and practice, but it is not difficult to learn. Here are the basic steps:

Clean the micrometer: Before using the micrometer, make sure it is clean and free of dust or debris. Use a soft cloth or brush to remove any dirt or particles from the measuring surfaces.

Adjust the micrometer: If the micrometer has a zero adjustment or a ratchet, use it to set the reading to zero. This will ensure that the measurement is accurate and consistent.

Position the micrometer: Position the micrometer jaws or spindle against the object you want to measure. Make sure the contact surfaces are flush and parallel to each other.

Take the measurement: Turn the thimble or ratchet to move the spindle towards the object until it contacts the surface firmly. Read the measurement from the scale on the thimble or sleeve. Make sure to read the scale from the correct side and take note of the units used.

Repeat the measurement: Take at least two or three measurements to ensure consistency and accuracy. If the readings are different, take the average or the closest value to the expected measurement.

Record the measurement: Write down the measurement and any other relevant information, such as the date, time, and object being measured. This will help you keep track of your measurements and make comparisons later on.

Accuracy of Micrometers

Micrometers are highly accurate measuring tools, capable of measuring to within a few thousandths of an inch or hundredths of a millimeter. However, their accuracy depends on several factors, such as the quality of the micrometer, the skill of the operator, and the conditions of the measurement. To ensure accurate measurements, it is important to use a high-quality micrometer, calibrate it regularly, and follow proper measurement techniques.

Calibration and Maintenance

Like all measuring tools, micrometers require regular calibration and maintenance to ensure accuracy and reliability. Calibration involves comparing the micrometer’s readings to a known standard and adjusting it if necessary. This can be done using a calibration block or gauge, or by sending the micrometer to a professional calibration service. Maintenance includes keeping the micrometer clean, lubricated, and free of damage or wear. It is also important to store the micrometer in a dry, protected place when not in use.

Advantages of Using Micrometers

Micrometers offer several advantages over other measuring tools, such as:

High accuracy and precision

Wide range of measurement capabilities

Easy to use and read

Durable and long-lasting

Compatible with various materials and shapes

Disadvantages of Using Micrometers

Despite their many advantages, micrometers also have some drawbacks, such as:

Relatively expensive compared to other measuring tools

Require skill and practice to use effectively

Limited to small or precise measurements

Can be affected by temperature, humidity, and other factors

Micrometer vs. Vernier Caliper

The vernier caliper is another common measuring tool used for small distance measurements. While similar to a micrometer in some ways, it has some important differences. A vernier caliper uses two sets of jaws, one for external measurements and one for internal measurements. It also has a sliding vernier scale that allows for greater accuracy than a regular scale. While both tools can be used for similar applications, micrometers are generally more precise and accurate for small measurements.

Micrometer vs. Dial Indicator

A dial indicator is a measuring tool used to detect small variations in distance or position. It consists of a spindle, a dial, and a spring-loaded plunger that contacts the surface being measured. While both tools can be used for similar applications, micrometers are generally more accurate and precise for linear measurements, while dial indicators are more suitable for detecting variations or deviations from a reference point.

Applications of Micrometers

Micrometers are used in a wide range of industries and applications, including:

Machining and manufacturing: Micrometers are used to measure the size and precision of components in machines, tools, and other equipment.

Engineering and construction: Micrometers are used to measure the thickness and dimensions of materials used in building and construction projects.

Science and research: Micrometers are used to measure the size and properties of microscopic particles, such as cells and molecules.

Medical and healthcare: Micrometers are used to measure the size and dimensions of medical instruments, implants, and other devices.

Automotive and aviation: Micrometers are used to measure the size and precision of engine parts, gears, and other components in vehicles and aircraft.

Conclusion

Micrometers are powerful tools that offer high accuracy and precision for measuring small distances and dimensions. They are widely used in various industries and applications, from manufacturing and construction to science and healthcare. While they require some skill and practice to use effectively, they offer several advantages over other measuring tools, such as wide range, easy-to-read scales, and durability. To ensure accurate measurements and reliable performance, it is important to use a high-quality micrometer, calibrate it regularly, and follow proper measurement techniques.

FAQs…..

What is the difference between a micrometer and a caliper?

A micrometer is a measuring tool used for small distances and dimensions, while a caliper is a measuring tool used for larger distances and dimensions. Micrometers are generally more accurate and precise than calipers.

How do you read a micrometer?

To read a micrometer, you need to read the scale on the thimble or sleeve and add it to the main scale reading. Make sure to read the scale from the correct side and take note of the units used.

How accurate are micrometers?

Micrometers are highly accurate measuring tools, capable of measuring to within a few thousandths of an inch or hundredths of a millimeter. However, their accuracy depends on several factors, such as the quality of the micrometer, the skill of the operator, and the conditions of the measurement.

How do you calibrate a micrometer?

To calibrate a micrometer, you need to compare its readings to a known standard and adjust it if necessary. This can be done using a calibration block or gauge, or by sending the micrometer to a professional calibration service.

What are the advantages of using a micrometer?

Micrometers offer several advantages over other measuring tools, such as high accuracy and precision, wide range of measurement capabilities, ease of use and reading, durability and compatibility with various materials and shapes.